See how our customers spend less money on repairs, have less equipment downtime, and see far fewer failures once they upgrade their equipment’s standard hydraulic oil filtration by installing Mag-Shield®. Check out our case studies and testimonials.

Case Studies

Mag-Shields® prevent expensive brake damage in fleet of CAT 777 haul trucks

Mag-Shield® magnetic filters effectively remove iron contamination before it can reach and embed into the brake discs. The need to replace expensive brake components following a hydraulic pump failure is eliminated.

Mag-Shield® capture debris from component failures, saving hydraulic systems from massive damage in a large fleet of CAT 797 haul trucks

Mag-Shield® magnetic filters save customer millions of dollars by preventing component failures from turning into system-wide, catastrophic failures.

Cylinder failures contained by Mag-Shield®

Mag-Shield® keep contamination caused by cylinder failures on a Hitachi EX850 excavator from circulating throughout the hydraulic system.

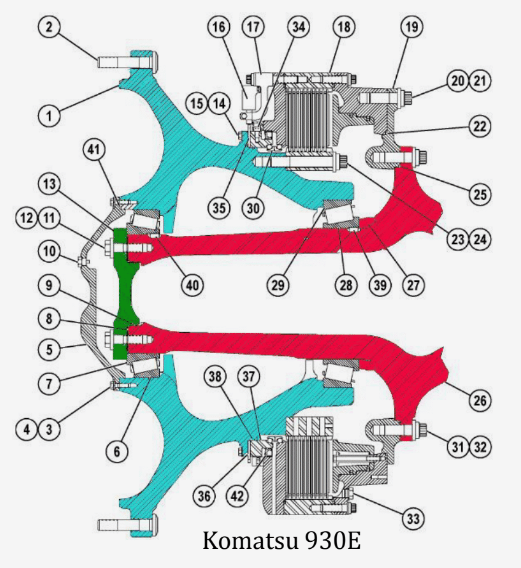

‘Safety-critical’ hydraulic systems guarded by installing Mag-Shield®

Mag-Shield® equipped in a Komatsu 930E keep damaging contamination from compromising critical steering and brake components.

Mag-Shield® installed in 120 new Komatsu 980E ultra-class machines

An equipment investment of this scale needs to include the most effective reliability strategies to ensure fleet availability and to achieve production targets.

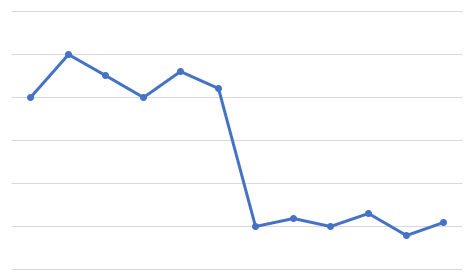

Mag-Shield® improve oil sample results in a CAT 797F haul truck

Mag-Shield® magnetic filters remove iron contamination resulting in lower oil sample baseline levels while preserving overall trends.

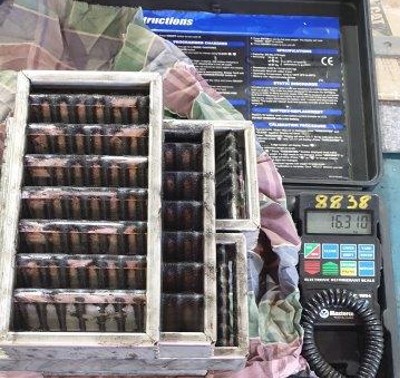

Much more iron removed than indicated by oil analysis during normal operation of CAT 994H equipped with Mag-Shield®

Mag-Shield® magnetic filters capture and contain ferrous particles released into the hydraulic fluid during normal operation.

The amount of contamination captured during a regular fluid life-cycle was impressive as was demonstrated by accurate measurements.

Mag-Shield® reduce false fluid contamination alarms in Hitachi EX5600 excavator

A Hitachi EX5600 was suffering from follow-on failures and a large number of false alarms from contamination sensors had resulted in premature replacement of parts. Mag-Shield® magnetic filters installed in the main hydraulic tank reduced the frequency of both the failures and the false alarms.

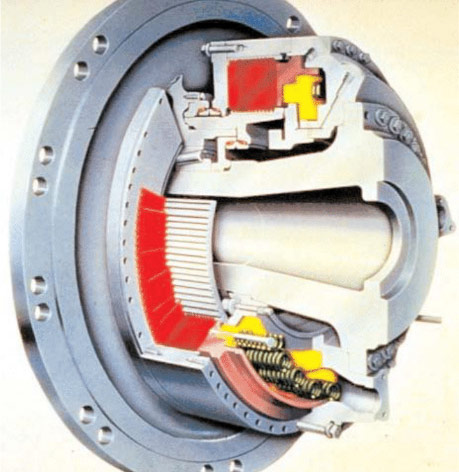

Mag-Shield® contain debris and prevent spread after torque converter failure

Mag-Shield® were officially specified for all fleets of trucks at this mining operation. Mag-Shield® captured the debris from a CAT 777D torque converter failure preventing total hydraulic system contamination and further damage.

Mag-Shield® and Mag-Probe® help filter Komatsu 830E wheel motors and front wheel hubs

Mag-Shield® provide wheel motor filtration and Mag-Probe® are used as a visual indicator of contamination levels in the front hubs and wheel motors of Komatsu 830E haul trucks.

Testimonials

“As professional engineer, consultant, educator and mining equipment performance researcher, I view BAY6 Solutions’ Mag-Shield® system as a major step forward in striving for best practice in mining tools hydraulic systems maintenance.”

Tim Joseph, Ph.D., P.Eng., FCIM.

“Keeping nearly a thousand pieces of mining machinery operating requires the best reliability strategies available. Here’s why we made Mag-Shield® an integral part of our mobile equipment fleets.”

Mike Hynes Superintendent of Reliability, North American Construction Group

Our Clients

- Aecon Mining Division

- Alberta Newsprint

- Anglo American

- Caterpillar

- Diavik Diamond Mine

- DTS Fluid Power

- Finning International

- Heavy Metal Equipment

- Imperial Oil Resources

- KMC Mining

- Komatsu America

- North American Construction Group

- Prairie Mines and Royalty Limited

- Teck Coal

- Teck HVC

- Shell Canada Energy

- SMS Equipment

- Suncor Energy

- Sunhills Mining LLP

- Syncrude Canada